Snapmaker J1s 3D Printer - High Speed IDEX Dual Extruder

Ex Tax: 960.66€

The Snapmaker J1 3D printer features an independent dual extruder (IDEX), ultra-fast print speed and alignment optimization. With cast and machined parts, linear rails, intuitive software and a user-centric design, the J1 is also refined and robust.

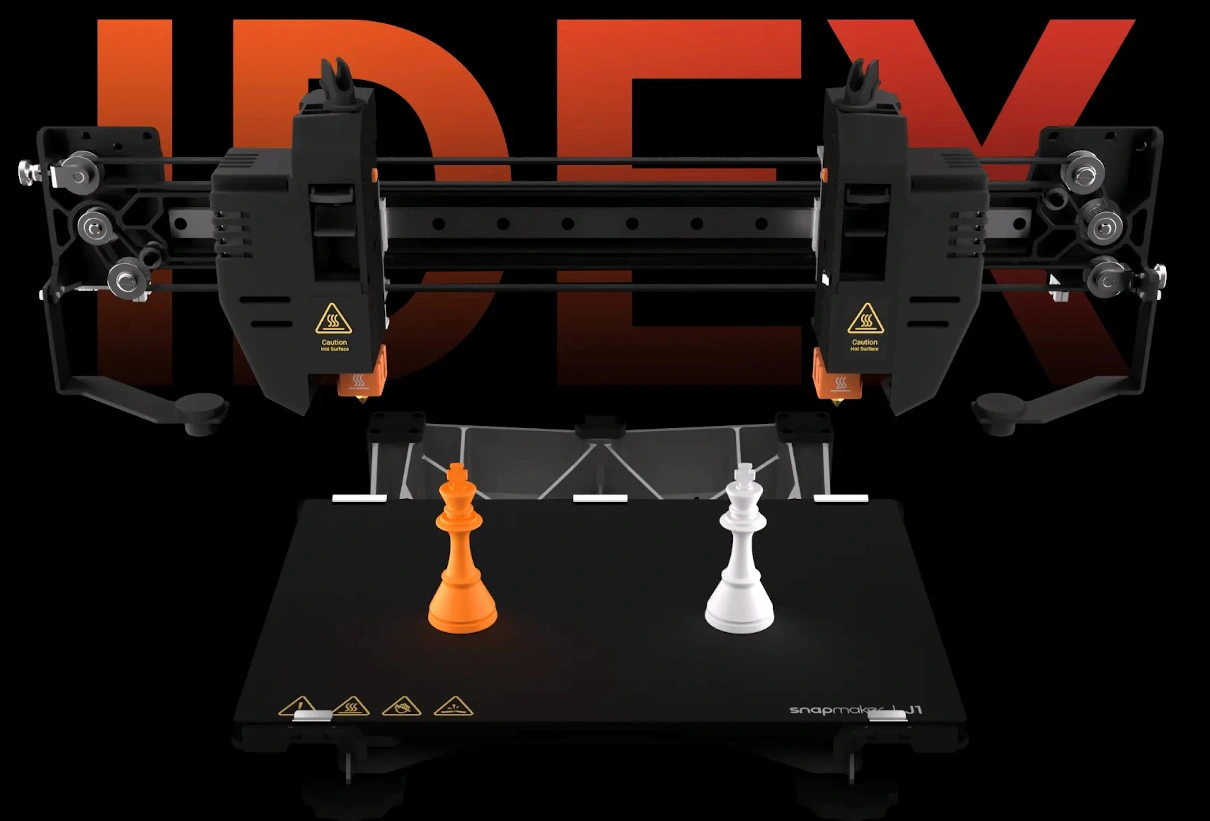

Quick index printing

Compared to a multi-material block in a single extruder, IDEX dual-material printing requires less filament change time and less waste. In addition, IDEX offers the cleanest dual-extruder solution that prevents cross-contamination.

Print in parallel

Cut your waiting time in half, double your productivity. IDEX is the only extrusion system with two separate extruders that move independently on the X-axis, so you can print two prints at the same time.

Copy Mode: Print two identical objects at once. It is especially suitable for batch printing, enabling studios and enthusiasts. If there is a problem with one of the prints, you can stop that print without affecting the other. This mode is a lifesaver when delivery is promised on a tight schedule.

Mirror Mode: The J1 directly mirrors your model and prints the original and the mirror in one go. For a symmetrical model, you can import half of it and print in mirror mode to reduce waiting time by 50%, perfect for quick drafts and concept models. As in copy mode, you can stop one print without affecting the other.

Vibration compensation

The J1 gives you a premium print speed of 350mm/s while delivering high resolution prints. This is possible due to the optimization of vibration compensation technology. This technology reduces vibration caused by high-speed movements, reducing ringing to improve print quality. With a maximum acceleration of 10,000 mm/s², you can efficiently implement small models full of details.

Switching and corner optimization of seamless extruders

In dual extrusion printing, the inactive extruder preheats when in standby mode and starts printing immediately after the extruder is active, which significantly reduces waiting time. By pre-analyzing the direction of movement of the extruders, the J1 can prevent problems such as corner bulging, ensuring better print quality in the corners.

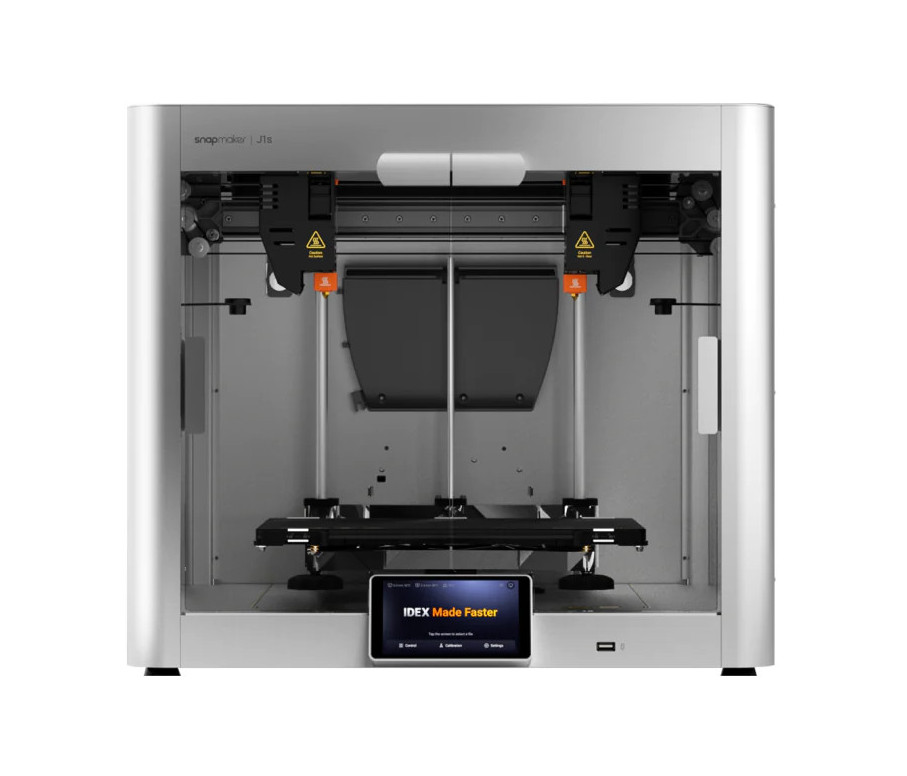

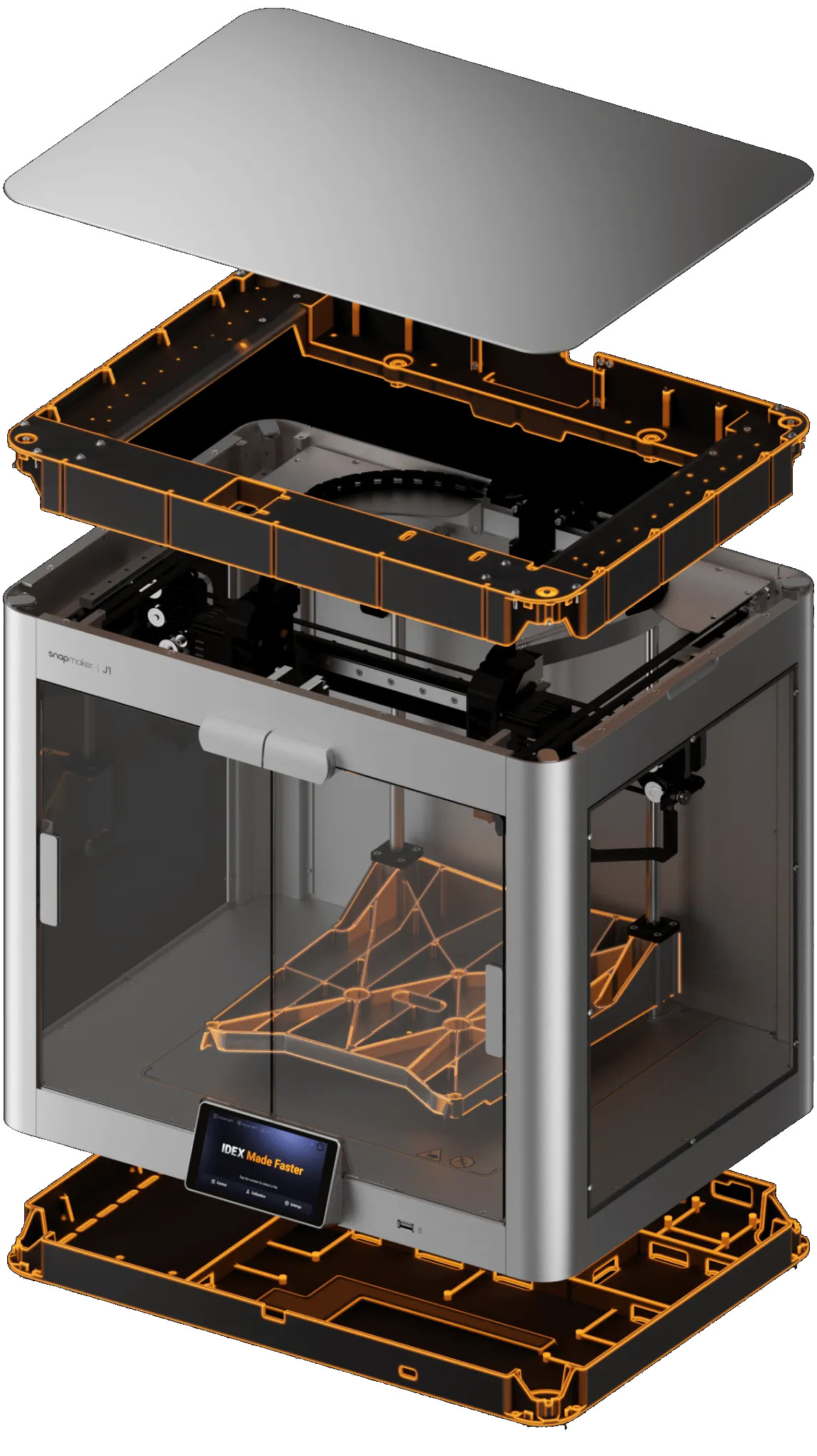

Speed comes from sophisticated hardware design

One-piece casting: The body of the J1 consists of a top frame and base made of one-piece casting and four aluminum alloy bars. Building the body from several highly integrated parts—an approach long used in the automotive industry—facilitates precise assembly. The J1 is so strong and reliable with minimal wobble and deformation that you can print large projects one after another for long periods of time with uncompromising print quality.

High Precision Linear Rails: Industrial-grade linear rails are CNC-milled to the micron level, ensuring smooth and stable motion. A big increase in precision, strength and durability so you can enjoy fast, accurate and stable production.

Aluminum Alloy Frame: The J1 inherits Snapmaker's iconic metal design, which is highly valued by users for its strength and durability. It provides better heat dissipation when the motherboard and power supply are distributed on the base, and the base material is aluminum alloy. All electronic components are well lubricated, as per your instruction.

Detachable and dissolving supports

Creating and removing supports can sometimes seem like rocket science, but we've done the math for you - consistent support, a clean interface, effortless removal and minimal post-processing required to maintain high dimensional accuracy. Breakaway suture provides the same support as conventional materials, but is much easier to remove without further processing. J1 supports PVA and other solubles. Absorb the impression and the supports will dissolve, resulting in a smooth surface and excellent dimensional accuracy. If you are looking for complex geometries, hollow structures and exquisite details, this is for you.

Two-material printing

You get the most out of two sets of features in one print. Combine the strength of nylon with the flexibility of TPU for functional parts. Also print multi-part objects. When not collected, the object acquires stronger interconnections and is therefore less vulnerable.

Advanced extruder technology

300°C hot ends: 300°C maximum nozzle temperature comes in handy when printing with high temperature filaments such as nylon, reinforced nylon and PC. With silicone hot end socks that prevent heat loss, the yarn melts and heats up much faster. Anti-clogging designs ensure that the flow is as smooth as possible.

Dual Direct Drive: Excellent extrusion precision to help extrude flexible filaments, combined with the high sensitivity of dual direct drives for faster, smoother and more precisely controlled deposition. It has a filament sensor that notifies you and pauses the print job if there is a filament leak, nozzle blockage, or other malfunctions that prevent the filament from loading.

Compact Extrusion Path: A compact extrusion path with a unique design allows for smooth printing on TPU and many other flexible materials.

Confined Space: Provides stable environmental conditions to ensure continuous operation of high temperature materials. For example, it prevents the deformation of ABS and many other materials.

Calibration is done easily

We use electrical conductivity to locate the two hot ends and the heated bed and measure the distances between the three objects, a creative solution to the complex IDEX calibration. This time saver allows you to complete the calibration in 10 minutes in assisted mode. By removing the calibration card and judgment call, errors are reduced and accuracy is achieved.

Handsfree XY Offset Calibration: When the two hot ends touch the square opening of the heated bed, it sends electronic signals to suggest their exact locations and the J1 calculates the offsets between them. The J1 then automatically compensates for offsets during printing to ensure perfect XY alignment, avoiding layer misalignment and improving the success rate of dual-material prints. This takes away the long learning curve and saves you from having to scrutinize too many lines. Tap start and lie down to increase accuracy.

Tool-Free Bed Leveling: A smooth print bed is the foundation of successful 3D prints, but bed leveling on IDEX printers can be time-consuming. Using a high-smooth PEI glass plate, the J1 can scale down from 3×3 (9-point) or 4×4 (16-point) leveling to 3-point level, with a 70-80% reduction in downtime. Turn the leveling dial as indicated on the touch screen and the bed will be leveled to adhere the first layer.

Easy-to-operate Z-shift calibration: Using electrical conductivity, the J1 can calculate the distances between the hot ends and the heated bed. So by adjusting the Z offset, we were able to reduce the back and forth movement of the calibration card. Just turn the thumb wheel as indicated on the touchscreen and you're now a Z-shift calibration guru!

Customized PEI glass plate

The J1 build plate is made of very flat glass, making the first layer smooth and sticky. Glossy glass on one side and PEI coating on the other side to help adhere to a variety of threads. The plate can be easily removed for particularly convenient maintenance and removal of prints.

Easily replaceable hot ends

Remove the two hot end screws, attach or replace the hot end, and get right back to printing. For adventure seekers looking for more options and advanced applications, we offer multi-diameter hot tips from 0.2 mm for precise detail to 0.8 mm for faster printing and hardened hot tips for engineering materials.

Integrated nozzle cleaners

Clean excess materials from nozzles and stop the flow from a freshly running extruder to free multi-material prints from stains and threads. The extruder can start a print job in sequence without waiting for the just active one to cool down. Switching extruders takes much less time, which again reduces downtime.

Specifications:

- Construction and technical details:

- - Used thread diameter: 1.75mm

- - Maximum nozzle temperature: 300 ºC

- - Open thread system: Yes

- - Extruder type: direct drive

- - Building area: 300x200x300mm

- - Maximum temperature of the construction plate: 100 ºC

- - Construction board surface: PEI

- - Construction panel material: glass

- - Fastening of the construction plate: clamp

- - Creation chamber during the process: open or closed

- - Extruder number: 2

- - Twin Extruder Construction Type: IDEX - Independent Twin Extruders

- Installation location / Requirements:

- - Total weight Total dimensions: 539x401x464mm

- - Total weight: 25 kg

- - Ambient working temperature: 10°C - 35°C

- - Maximum power consumption: 400W

- - AC voltage:

- - 100V - 240V, 4.4A (50-60 Hz)

- - DC: 24V

- Equipment:

- - Hepa filter: No

- - Touchscreen: Yes

- - Internal memory: Yes, 8 GB

- Connection:

- - USB port: Yes

- - WLAN: Yes

- Accuracy:

- - Layer height: 0.05 - 0.3mm

Claim orders from Stores

You can claim your purchased items within 1 - 4 work days after making an order (if product is in local warehouse).

Please wait for an email notification regarding Your order status update.

Vilnius Store address: Vytenio g. 20, LT-03229 Vilnius, Lietuva

Kaunas Store address: Pramonės pr. 4D, LT-51329, Kaunas, Lietuva

Local delivery in Lithuania

Purchased items are delivered locally through Venipak service. Depending on availability of items, orders are processed within 1-3 work days. Orders made until 1AM are shipped the same day.

Local delivery (1-4 w.d.) price for items of any size is through through courier service is 4.90€ (incl. VAT), if the amount of the shopping cart exceeds 150€ - delivery is free.

Local delivery price to Venipak parcel terminals (1-3w.d.) is 2.90€ incl. VAT, if the amount of the shopping cart exceeds 50€ - delivery is free.

Local delivery price to Omniva parcel terminals (1-3w.d.) is 3.90€ incl. VAT,if the amount of the shopping cart exceeds 70€ - delivery is free.

Payment on delivery (COD) +2.00€ (incl. VAT).

You can pay for the goods at the time of delivery to the courier in cash or by credit card. Payment to Omniva parcel terminals is only possible by bank card.

A separate delivery fee applies to oversized items, regardless of the amounts and conditions stated above.

International delivery pricing through courier service

International shipping prices depend on geographic location:

Latvia - 5.50€ (incl. VAT)

Estonia - 6.50€ (incl. VAT)

Paid orders of more than 150€ are shipped for free to Latvia and Estonia.

other countries - negiotiated individually.

International delivery pricing to Omniva/Venipak parcel terminals

Latvia - 6.00€ (incl. VAT)

Estonia - 8.50€ (incl. VAT)

Payments:

We accept payments via PayPal for orders over 20€.

Product availability status:

Vilnius Store In Stock - the product is at the store, Vytenio str. 20 in Vilnius and can be picked up / purchased at same day;

Kaunas Store In Stock - the product is at the store, Pramonės pr. 4D in Kaunas and can be picked up / purchased the same day;

Central Warehouse In Stock - In stock, product will be shipped in a short time 1-2 work days;

1-2 work days - product will be shipped in a short time - 1-2 business days;

2-3 work days – we don’t have selected product in local warehouse. Shipping time is only 2-3 work days;

3-5 work days – we don’t have selected product in local warehouse. Shipping time is between 3-5 work days;

3-7 work days – we don’t have selected product in local warehouse. Shipping time is between 3-7 work days;

Out of Stock – selected product is sold out at the moment, but you can apply for automatic alert by email when product will be in stock.