Raspberry Pi 5 and kitsRaspberry Pi 4 and kitsRaspberry Pi 3B+ and kitsRaspberry Pi 400/500Raspberry Pi Zero and accessoriesRaspberry Pi PicoRaspberry Pi CMScreens for Raspberry PiRaspberry Pi Camera modulesCases for Raspberry PiHAT extension for Raspberry PiRaspberry Pi 3/2/+ accessoriesPower Supply for Raspberry PiRaspberry Pi memory cards with NOOBS

STM32 MicrocontrollersATmega microcontrollersFlipper ZeroTeensy - ARMAdafruit FeatherESP8266 / ESP32 WiFi ModulesM5Stack controller and accessories

Security camerasTuya Smart LifeBlitzWolfGate Automation SystemsBleBox WiFi Smart SwitchHousehold FansSwitchBotSmart LightingSmart SensorsClimate ControlSmart PlugsSmart Control DevicesSmart Locks and Access ControlSmart devices for petsHealth and personal care productsSmart Home Accessories

Sensors - modulesWireless Communication ModulesRelay modulesLCD/OLED/TFT DisplaysMotor controllersProgrammers and convertersConnectorsSwitchesVoltage RegulatorsBasic Starter KitPrototypingAudio Amplifiers / Speakers / OtherLED DiodesPassive electronic componentsActive electronic componentsElectromagnets and solenoidsCoolingWearable electronics and materials

Servo motors and accessoriesDC motorsStepper motorsVibration MotorsBrushless Motors and ControllersElectric Linear Actuators and CylinderWater pumpsStepper Motor MountsWheels and mounting parts for motors

AC voltage stabilizerAdjustable Lab Power SuppliesInverters DC/ACUninterruptible power supplyAlkaline BatteriesRechargeable batteryPower Supply AccessoriesBattery Chargers Ni-Mh / Ni-Cd / Li-Ion / Li-Pol / Li-FeLi-Ion battery charging and balancing boardsAC/DC Mains powers supply adapterPower Supplies AC/DCConnection Cables, ExtendersBatteries for power toolsPlug adapter EU/UK/USCharger for Electric Bikes

Soldering toolsBattery Welding Machines and accessoriesMeasuring equipmentChemicalsTweezersElectric toolsScrewdrivers and wrenchesHot Glue GunPlier and cutting nipperInsulation removal and crimping toolKnives and scissorsElectric engraver toolsMagnifying glassesInsulating materialsFlashlightPlastic enclosureStorage boxes and OrganizersUltrasonic cleanersLabel printersAIRCELL Air Cushion

CNC machines and accessoriesAluminum Extrusion ProfilesLinear ActuatorBrackets and Other Accessories for Aluminium ProfilesLinear guides and garriagesRollers on supportsTrapezoidal Screws and NutsLinear Steel RodsLinear bearingsBearingsTiming BeltsTiming PulleyLinear Rod SupportSpindle motors, converters and mount bracketsScrews and NutsCable ChainsDrills and Cutters

AEON Laser Engraving Cutting MachineFiber Metal Marking LaserCO2 Galvo engraving-marking machineUV Marking machineFLUX Laser Engraving Cutting MachinexTool LASER AND BLADE CUTTING MACHINEDiode laser engraving laserLaser machine spare parts and accessoriesEngraving MaterialsLightBurn Software

3D Printers3D scanner3D Pens3D Printing filamentsSLA 3D Printing resin3D Printer maintenance and cleaning3D Printer parts

Educational kits for beginnersEducational kits for advancedSNAP CIRCUITS kitsAbilix Krypton roboticsRobobloq roboticsLEGO Education

USB cablesVideo cables and connectorsUSB HUBComputer network cablesNetwork equipmentData storages and their accesoriesAudio cables and connectorsSpeakers activeKeyboard and MouseMicrophonesGamingLaptop AcessoriesComputer Power SuppliesCable OrganizersMonitorsWebcamsProjectorsUPS Uninterruptible power supplyOther Computer Accessories

Power BankHeadphonesMobile phone chargersPhone casesSelfie stickSmart WatchesPhone batteriesPortable speakers

Jump StartersCar Dash CamerasPhone holdersCarPlay and Android AutoMotorcycle IntercomsUSB car chargersCar FM modulatorEV Car accessoriesCar StorageCar diagnostic equipmentCar Cleaning ToolsMini CompressorsParking HeatersCar fuses and holdersLight sources

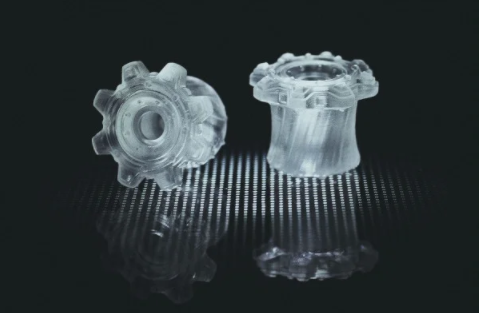

Resin for 3D printer FormFutura Platinum LCD Series 0.5kg - Clear

Clear photopolymer resin used in open source 3D printers. It is cured by light of 385 nm to 420 nm wavelength, emitted by DLP and LCD projectors. The product may emit an unpleasant odor of low intensity during operation. A characteristic feature of resins from this line is short exposure time. The finished models obtained from FormFutura Platinum LCD Series are characterized by a high level of detail and smooth surface. Package contains 0.5 kg of product.

Main features of the Platinum LCD Series resins

- Emits a small amount of odor during printing

- Resistance to weather conditions and UV radiation

- Faster printing due to short exposure time

- Produce high-resolution, highly detailed models

- Offers vibrant, long-lasting colors without discoloration (available in translucent and opaque versions)

- Resins have low shrinkage and water absorption (absorbency)

- Used in model and figure printing and functional prototyping

Steps to be taken before starting printing

- Shake the bottle for at least 2 minutes before each use.

- Then leave the resin for about 10 minutes to let the air bubbles escape from the resin

- After printing, unused resin can be transferred from the printer tank to the bottle

Final processing of the finished 3D printout

- Ready model should be rinsed in isopropyl alcohol (IPA) or bioethanol for about 5 minutes.

- The manufacturer recommends the use of ultrasonic cleaner.

- Before further curing check if the model is completely dry after rinsing

- Place the rinsed parts in a well-ventilated room for at least 30 min. (Compressed air can also be used for at least 2 minutes).

- Cure the objects in a special chamber for 20 to 30 minutes at 65°C

- Recommended curing wavelength is from 300 nm to 420 nm

- When grinding resin, respiratory protection is absolutely necessary

Specification:

- Viscosity: 500 cps at 25°C

- Density: 1.18 g/cm2

- Glass transition temperature (Tg) 51°C

- Water absorption 0,4%

- Impact strength (IZOD) 18 J/m

- Tensile Strength 45 MPa

- Tensile Resilience 1000 MPa

- Elongation at tension 8%

- Bending Strength 66 MPa

- Elasticity 1800 MPa