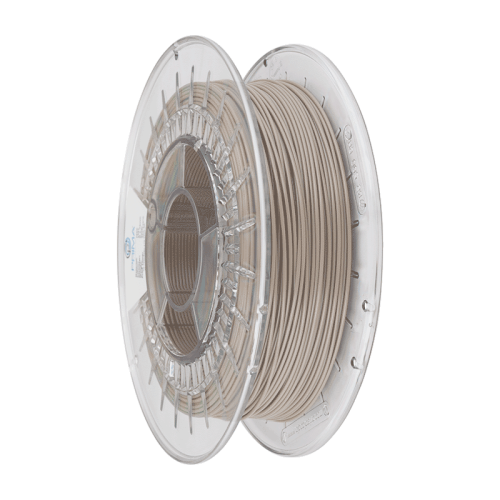

PrimaSelect Luvocom 3F PEEK 9581 - 1.75mm - 500g - Natural

Product Code: PRM-5384

Availability: 4-7 business days

Planuojama gavimo data po užsakymo: 2025-04-21

Ex Tax: 248.76€

PEEK is most often used to replace different polymer and metal components in cars, machines and airplanes. Thanks to a very high heat and chemical resistance PEEK can be used in many ways as metal components are usually used. It can retain its properties at high service temperatures over a long time. PEEK is also used in the medical field as it is perfect to make customized prosthetic parts such as arms, hands and cranial implants.

For a long time, PEEK was one of the hardest materials to 3D print but after much research, an additive was invented and the PEEK Luvocom 9581 was introduced. This new additive has changed the way PEEK can be used as it is now made to work better with FDM 3D printers.

The SELECT Peek never comes in contact with water during the manufacturing process and is directly packed in vacuum-sealed bags. This and the additive create a PEEK filament with excellent layer adhesion which of course greatly improves the impact resistance, durability, strength and also makes the printing process much easier than with regular PEEK.

To make a successful PEEK 3D print there are a few things to keep in mind. Your 3D printer must have the performance to meet the PEEK filament requirements. The PEEK filament should be 3D printed with a nozzle temperature of 360 - 400 °C. The heat bed should be set to 120 °C and a heated building chamber is important to have. Also ensure, that your 3D printer is placed in a room, where are hardly any draft and temperature fluctuations. PEEK is best 3D printed on a PEI sheet at a printing speed of 15-30 mm/s.

Main features:

- 3D print strong parts – very high chemical & heat resistance

- One of the most used high-performance thermoplastics

- Replace metal components and safe manufacturing costs

- Much easier than other PEEK filaments to 3D print

- Manufacture resistant parts for the aerospace, gas, oil, medical, automotive and many more industries

- Filament Type: PEEK 9581

- Diameter: 1,75 mm

- Tolerance: 0,05 mm

- Weight: 0,50 kg

- Length: 155 m

- Recommended Printing Temp. Min.: 350 ºC

- Recommended Printing Temp. Max.: 380 ºC

- Recommended Printbed Temperature Min.: 120 ºC

- Recommended Printbed Temperature Max.: 160 ºC

- Recommended Printing Speed Min.: 15 mm/s

- Recommended Printing Speed Max.: 30 mm/s

- Specific gravity: 1,34 g/cm3, ASTM D72

- Mold Shrinkage: 1,0-1,6%

- Tensile strength: 95 MPa, ISO 527

- Tensile modulus: 3440 MPa, ASTM D638

- Elongation at yield: 5%, ISO 527

- Flexural Strenght: 150%, ISO 178

- Flexural Modulus: 2500, ISO 178

- Impact Strength: 7 KJ/m2, ISO 1791eA

Claim orders from Stores

You can claim your purchased items within 1 - 4 work days after making an order (if product is in local warehouse).

Please wait for an email notification regarding Your order status update.

Vilnius Store address: Vytenio g. 20, LT-03229 Vilnius, Lietuva

Kaunas Store address: Pramonės pr. 4D, LT-51329, Kaunas, Lietuva

Local delivery in Lithuania

Purchased items are delivered locally through Venipak service. Depending on availability of items, orders are processed within 1-3 work days. Orders made until 1AM are shipped the same day.

Local delivery (1-4 w.d.) price for items of any size is through through courier service is 4.90€ (incl. VAT), if the amount of the shopping cart exceeds 150€ - delivery is free.

Local delivery price to Venipak parcel terminals (1-3w.d.) is 2.90€ incl. VAT, if the amount of the shopping cart exceeds 50€ - delivery is free.

Local delivery price to Omniva parcel terminals (1-3w.d.) is 3.90€ incl. VAT,if the amount of the shopping cart exceeds 70€ - delivery is free.

Payment on delivery (COD) +2.00€ (incl. VAT).

You can pay for the goods at the time of delivery to the courier in cash or by credit card. Payment to Omniva parcel terminals is only possible by bank card.

A separate delivery fee applies to oversized items, regardless of the amounts and conditions stated above.

International delivery pricing through courier service

International shipping prices depend on geographic location:

Latvia - 5.50€ (incl. VAT)

Estonia - 6.50€ (incl. VAT)

Paid orders of more than 150€ are shipped for free to Latvia and Estonia.

other countries - negiotiated individually.

International delivery pricing to Omniva/Venipak parcel terminals

Latvia - 6.00€ (incl. VAT)

Estonia - 8.50€ (incl. VAT)

Payments:

We accept payments via PayPal for orders over 20€.

Product availability status:

Vilnius Store In Stock - the product is at the store, Vytenio str. 20 in Vilnius and can be picked up / purchased at same day;

Kaunas Store In Stock - the product is at the store, Pramonės pr. 4D in Kaunas and can be picked up / purchased the same day;

Central Warehouse In Stock - In stock, product will be shipped in a short time 1-2 work days;

1-2 work days - product will be shipped in a short time - 1-2 business days;

2-3 work days – we don’t have selected product in local warehouse. Shipping time is only 2-3 work days;

3-5 work days – we don’t have selected product in local warehouse. Shipping time is between 3-5 work days;

3-7 work days – we don’t have selected product in local warehouse. Shipping time is between 3-7 work days;

Out of Stock – selected product is sold out at the moment, but you can apply for automatic alert by email when product will be in stock.