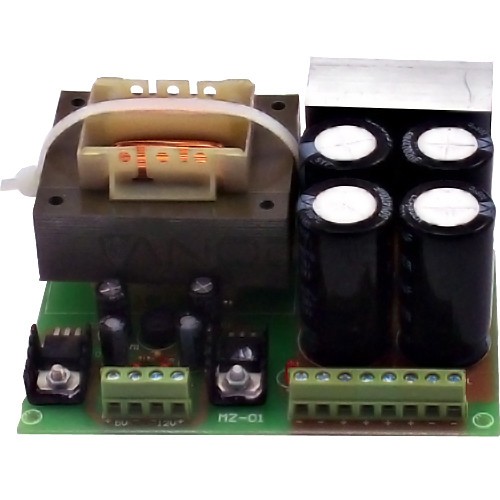

MZ-01 power supply module

Product Code: MX-MZ-01

Availability: 6-11 business days

Planuojama gavimo data po užsakymo: 2025-03-21

Ex Tax: 48.51€

The MZ-01 module is used to power electronic devices requiring high-power, unstabilized voltage. The main application is to power stepper motor controllers and peripheral elements used in CNC control systems. It has an unstabilized power supply for the final stages and a separate stabilized 5 and 12 V power supply. It is designed to work with transformers with a rated power of up to 500W. The module has LED indication of the presence of each voltage. The device is delivered without a power transformer. which we choose according to our needs.

The basic MZ-01 block is made on the basis of a generally available unstabilized power supply application. It consists of two KBU10M rectifier bridges with parameters of 10A and a maximum voltage of 1000V and four filter capacitors connected in parallel with a capacity of 4700 µF/50V. The second low-voltage block is made of a TS 15/A transformer powered by a 0.5A fuse. rectifier bridge with a current of 1A and a maximum voltage of 1000V. filter capacitors and two integrated stabilizers from the 78XX series. The input circuit of the stabilizers uses a filter consisting of a 470µF capacitor with a voltage of 25V. and in the output circuit. 100µF capacitors at 25V. The connection system was made based on the manufacturer's application note. ARK 1.5 mm² connectors with a maximum voltage of 250V and a forward current of 16A were used to make connections to external devices.

Electronic components exposed to an increase in internal structure temperature are placed on aluminum heat sinks. Components. from which the MZ-01 module was made meet the European Union's RoHS directive (Restriction of use of certain Hazardous Substances) regarding environmental protection. The device is made using lead-free technology. The binder used to assemble the device contains 99% tin and 1% copper.

Advantages of the MZ-01 power supply module:- high performance.

- low cost.

- small dimensions.

- 230 V AC power supply. 50 Hz.

- possibility of connecting a transformer with an output voltage of up to 35VAC.

- output current 2 x 7A.

- additional low-voltage power supply.

| Module supply voltage | 230V AC. 50 Hz |

| Maximum input voltage (AC output of the transformer connected to the module) | 35VAC |

| Maximum transformer winding current - one winding - two identical windings | 7A 2 x 7 A |

| Output voltage of the stabilized power supply | 5V. 12V + 10% |

| Maximum current of the stabilized power supply (5 and 12 V outputs have a load capacity of 1A each, but the sum of their currents cannot exceed 1 A) | 1A |

| Cooling | Passive or forced circulation | ||

| Environment | Place | Avoid dust. oil and corrosive gases | |

| Temperature | surroundings | 0°C - 50°C | |

| storage | 0°C - 50°C | ||

| Humidity | 30% - 75% RH (non-condensing) | ||

| Dimensions [mm] | Length | 112 | |

| Width | 102 | ||

| Height | 45 | (the height depends on the 4700µF capacitors used) | |

| Weight [kg] | ~0.645 | ||

The dimensions from the table are marked in the drawing below:

| PIN | Function |

|---|---|

| NL | Power input 230VAC. 50Hz universal power supply module. N-neutral wire. L-phase wire. |

| LN | Power output 230VAC. 50Hz to the external transformer of the high-current part of the universal power supply module. L-phase wire. N-neutral wire. |

| *A.C | Input of the first winding from the external transformer of the high-current part. The pin marked with a dot is the beginning of the winding. |

| *A.C | Input of the second winding from the external transformer of the high-current part. The pin marked with a dot is the beginning of the winding. |

| PIN | Function |

|---|---|

| - | Exit. Power supply ground for the high-current part. All pins marked with "-" are connected in parallel. |

| + | Exit. Plus DC power supply for the high-current part. All pins marked with a "+" sign are connected in parallel. |

| Signal | Function |

|---|---|

| -12V+ | Output of an additional 12VDC low-voltage power supply. "+" means the output of the system. "-" is mass. |

| +5V- | Output of an additional 5VDC low-voltage power supply. "+" means the output of the system. "-" is mass. |

The diodes indicate the operating status of the power supply. Each of the three red diodes indicates the presence of individual voltages (5V, 12V and high depending on the transformer used).

Description of the construction of the MZ-01 universal power supply module Operation of the MZ-01 power supply Connecting the power supply to the 230V network. 50Hz The MZ-01 universal power module can work independently. generating 5 and 12 VDC voltage from the built-in stabilized power supply.

Attention!!!

Particular attention should be paid to the total current of the low-voltage block. which cannot exceed the value of 1A. Means. that I5VDC + I12VDC < 1A

To use the device in the configuration described above, simply connect 230V alternating voltage to the NL connector (description in chapter 4. Construction of the MZ-01 power supply module -> P1 connector pins).

Second. the more important function of the module is the high-current block built on the basic application of an unstabilized power supply. The main application of the device manufactured by our company is the distribution of electricity in the control cabinets of numerical machine tools. so the rest of the instructions will be based on the requirements set for them.

To start both MZ-01 blocks, connect the 230VAC power supply as described above and use an additional external transformer.

A properly selected power supply will allow you to fully use the capabilities of stepper motors. The transformer is selected based on the supply voltage of the final stages of the controllers and the current that will be generated for the motors. To calculate the basic parameters of the transformer, let's use the following line of thought:

Maximum supply voltage of controllers: e.g. 50VDC. We need to pay attention to this. that this is a limit value. The EMF voltage (generated by the motor coils during reversals) can reach 5-10% of the potential value applied to the controller power pins. This should be taken into account when selecting the source. Based on this statement, we subtract UEMF from UVCC(max)

50V – (10% of 50V) = 50V – 5V = 45V

It is suggested to use a power supply with an output voltage not exceeding +45V. leaving room for power surges and EMF return. Higher potential may damage the controller.

Voltage of the transformer secondary side.

To calculate the required voltage value of the transformer secondary winding, divide the result of the above calculations by the square root of two (approximately 1.41).

45V / 1.41 = 31.92V

In this way, we obtained an approximate value of the voltage of the transformer secondary winding. If we do not have a device with such a potential, we use the closest value in the series. Manufacturers standardize production and we cannot always buy an identical product for calculations. In our case, we can choose between 32VAC or 28VAC. We will apply the first one.

Attention!!!

Please remember. that the voltage value of the transformer secondary winding cannot exceed 35VAC. A higher potential may damage the capacitors in the power supply module.

The power source may have a lower current than the motor rating (typically 50% ~ 70% of the motor current). It follows from this. that the controller draws current from the power supply capacitor only when the PWM cycle is ON. and it doesn't download. when the cycle is OFF. So the average current draw from the power source is much lower than the motor current. For example, three 3A motors can be easily powered from a 6.3A source.

Powering several controllers from a single power source is permitted under certain conditions. that the source has the appropriate current capacity. Below is the formula for calculating the current efficiency of the source.

(Number of motors * motor rated current) * 70% = source rated current

It's good to add some extra power. i.e. plus 5 - 10% of the value. which we found above.

Calculation for the example from the text above:

(3 * 3A) * 70% = 6.3A

6.3 A * 1.1 = 6.93 A

(round up to 7A)

In this way, we calculated the current needed to power three stepper motor drivers. To calculate the required transformer power value, we multiply the calculated voltage and current of the secondary winding:

32V x 7A = 224 VA

After receiving the result, we once again use the normalized power values of the transformers. The calculated 224 VA is rounded up. Depending on the manufacturer, it will be 240. 250 VA. Please keep this in mind. that one AC input of the power supply can carry a maximum current of 7A. If we want to obtain higher currents from the power supply module, we should use a transformer with two identical secondary windings (identical output voltages on the secondary side) - then the output current will be the sum of the currents from the two windings. This solution increases the efficiency up to 14A.

Attention!!!

When connecting the windings in parallel, remember this. so that they have identical voltages and are correctly connected to the power supply board (in accordance with the phases).

When connecting the transformer to the MZ-01 module, pay attention to the proper connection of the windings:

a) in the case of a transformer with one winding, connect it to one of the AC inputs.

b) with a double secondary winding of the transformer, pay attention to the phase polarization. When connecting, follow the markings on the transformer and the power supply board. We check individual phases and find the beginnings of the windings. Once you have located the above mentioned. we install them in the pins of the AC connector. The beginnings or ends of both windings should be connected to the AC inputs marked with a dot.

An overview diagram is provided below.

Attention!!!

Inverted or incorrect connection of the transformer secondary wires will result in a short circuit on the rectifier bridges. This may lead to irreversible damage to the device and/or transformer.

To protect the transformer, a fuse with a response current appropriate to its power should be used at the power input of the primary winding.

When using transformers above 200 W, the system should be powered using a soft start system. SOFT START start prevents the generation of a current impulse in the windings. that appears when you turn it on to the network. High transformer power. use of a rectifier and high-capacity filter capacitors in the system. causes. that when such a system is connected to the network, the current it consumes is greater than its rated current. causing the fuses to trip. which will disconnect our power supply. This is especially troublesome in the case of. when a computer and a machine controller are connected to one power strip. When the fuse trips, the computer will turn off. causing loss of unsaved data. By using the SOFT START system, we eliminate this situation and we can work without any worries on the computer and machine controller connected to one power strip (one fuse).

The installation diagram of SOFT START -> MZ-01 module -> transformer is provided below.

Please remember this when connecting. so that the cross-sections of the cables supplying the stepper motor controllers are appropriately selected for the currents that will be drawn from the module. It is also recommended to use fuses on the outputs powering individual axes of the universal numerical controller. For group power distribution in various types of low-voltage systems (power distribution), we can use the FM-01 module produced by our company. It has one input via a six-pin ARK connector. We connect three of them to the "+" of the power supply. the rest with "-". The module has four independently protected outputs. Each of them has a fuse and voltage indication. Damage to the fuse is visualized by turning off the appropriate LED. The module accepts voltage in the range: 5 V ÷ 80 V DC.

To avoid interference, do not connect controllers to the power supply in series. Each controller should be connected with separate cables (parallel connection).

How to connect the module with a set of drivers.

ATTENTION!!!

Never reverse the polarity of the power supply. because it will damage the driver!!!

In case the power supply module does not work properly. the first step should be to check whether the problem is electrical or mechanical (lack of connections). It is important to. to document every step in solving the problem. You may need to use this documentation at a later date. and the details contained therein will greatly help our Technical Support employees solve the problem. Many errors in a traffic control system can be related to electrical noise. software errors in the control device or errors in cable connection.

Below is a table with the most common problems. with which customers contact our Technical Support.

| Symptoms | Probable cause of the fault | Procedure |

|---|---|---|

No voltage 5 and 12V | No 230VAC power supply Damaged fuse on the MZ-01 module board No connection to the receiver | We visually check the lighting of individual LEDs indicating the presence of voltages on the device. If there is no voltage, disconnect the power supply to the control cabinet and check the operation of individual fuses. We replace damaged ones with new ones compatible with the system application. We check the system's cabling and connections |

| No supply voltage for stepper motor drivers | Damaged fuse on the transformer power supply Damaged fuse in the controller power supply No connection to the receiver | We visually check the lighting of individual LEDs indicating the presence of voltages on the device. If there is no voltage, disconnect the power supply to the control cabinet and check the operation of individual fuses. We replace damaged ones with new ones compatible with the system application. We check the system's cabling and connections |

| High temperature of the stabilizer heat sink | Too much load on the low voltage power supply | We perform calculations and prepare a balance of currents drawn from the power supply. We correct and remove unnecessary burden. |

| High temperature of the heat sink of the rectifier bridges of the high-current part | Too high load on the high-current power supply High value of consumed current | We perform calculations and prepare a balance of currents drawn from the power supply. We correct and remove unnecessary burden. When drawing currents greater than 5 A, it is recommended to force air around the rectifier bridges to better dissipate excess heat. |

The MZ-01 power module is designed for continuous operation. does not require any preparatory work on the part of the user. Please keep this in mind. That :

A dangerous mains voltage of 230VAC will be generated on the module board

The secondary voltage from the transformer can reach 35 VAC, which after rectification gives 50 VDC and with high current efficiency, this voltage is as dangerous as the mains voltage.

After turning off the power supply, voltage remains on the filter capacitors for some time, which in the event of a short circuit at the power output may cause a spark and/or damage to the module.

When drawing currents greater than 5 A, it is recommended to force air around the rectifier bridges to better dissipate excess heat.

* The value of the output current and voltage depends on the transformer used.

The value of the output voltage is proportional to the supply voltage and is influenced by the output current.

Current: 14 A*

Auxiliary voltage: 5 and 12 VDC

Max. motor voltage: 50 VDC *

Claim orders from Stores

You can claim your purchased items within 1 - 4 work days after making an order (if product is in local warehouse).

Please wait for an email notification regarding Your order status update.

Vilnius Store address: Vytenio g. 20, LT-03229 Vilnius, Lietuva

Kaunas Store address: Pramonės pr. 4D, LT-51329, Kaunas, Lietuva

Local delivery in Lithuania

Purchased items are delivered locally through Venipak service. Depending on availability of items, orders are processed within 1-3 work days. Orders made until 1AM are shipped the same day.

Local delivery (1-4 w.d.) price for items of any size is through through courier service is 4.90€ (incl. VAT), if the amount of the shopping cart exceeds 150€ - delivery is free.

Local delivery price to Venipak parcel terminals (1-3w.d.) is 2.90€ incl. VAT, if the amount of the shopping cart exceeds 50€ - delivery is free.

Local delivery price to Omniva parcel terminals (1-3w.d.) is 3.90€ incl. VAT,if the amount of the shopping cart exceeds 70€ - delivery is free.

Payment on delivery (COD) +2.00€ (incl. VAT).

You can pay for the goods at the time of delivery to the courier in cash or by credit card. Payment to Omniva parcel terminals is only possible by bank card.

International delivery pricing through courier service

International shipping prices depend on geographic location:

Latvia - 5.50€ (incl. VAT)

Estonia - 6.50€ (incl. VAT)

Paid orders of more than 150€ are shipped for free to Latvia and Estonia.

other countries - negiotiated individually.

International delivery pricing to Omniva/Venipak parcel terminals

Latvia - 6.00€ (incl. VAT)

Estonia - 8.50€ (incl. VAT)

Payments:

We accept payments via PayPal for orders over 20€.

Product availability status:

Vilnius Store In Stock - the product is at the store, Vytenio str. 20 in Vilnius and can be picked up / purchased at same day;

Kaunas Store In Stock - the product is at the store, Pramonės pr. 4D in Kaunas and can be picked up / purchased the same day;

Central Warehouse In Stock - In stock, product will be shipped in a short time 1-2 work days;

1-2 work days - product will be shipped in a short time - 1-2 business days;

2-3 work days – we don’t have selected product in local warehouse. Shipping time is only 2-3 work days;

3-5 work days – we don’t have selected product in local warehouse. Shipping time is between 3-5 work days;

3-7 work days – we don’t have selected product in local warehouse. Shipping time is between 3-7 work days;

Out of Stock – selected product is sold out at the moment, but you can apply for automatic alert by email when product will be in stock.