Raspberry Pi 5 and kitsRaspberry Pi 4 and kitsRaspberry Pi 3B+ and kitsRaspberry Pi 400/500Raspberry Pi Zero and accessoriesRaspberry Pi PicoRaspberry Pi CMScreens for Raspberry PiRaspberry Pi Camera modulesCases for Raspberry PiHAT extension for Raspberry PiRaspberry Pi 3/2/+ accessoriesPower Supply for Raspberry PiRaspberry Pi memory cards with NOOBS

STM32 MicrocontrollersATmega microcontrollersFlipper ZeroTeensy - ARMAdafruit FeatherESP8266 / ESP32 WiFi ModulesM5Stack controller and accessories

Security camerasTuya Smart LifeBlitzWolfGate Automation SystemsBleBox WiFi Smart SwitchHousehold FansSwitchBotSmart LightingSmart SensorsClimate ControlSmart PlugsSmart Control DevicesSmart Locks and Access ControlSmart devices for petsHealth and personal care productsSmart Home Accessories

Sensors - modulesWireless Communication ModulesRelay modulesLCD/OLED/TFT DisplaysMotor controllersProgrammers and convertersConnectorsSwitchesVoltage RegulatorsBasic Starter KitPrototypingAudio Amplifiers / Speakers / OtherLED DiodesPassive electronic componentsActive electronic componentsElectromagnets and solenoidsCoolingWearable electronics and materials

Servo motors and accessoriesDC motorsStepper motorsVibration MotorsBrushless Motors and ControllersElectric Linear Actuators and CylinderWater pumpsStepper Motor MountsWheels and mounting parts for motors

AC voltage stabilizerAdjustable Lab Power SuppliesInverters DC/ACUninterruptible power supplyAlkaline BatteriesRechargeable batteryPower Supply AccessoriesBattery Chargers Ni-Mh / Ni-Cd / Li-Ion / Li-Pol / Li-FeLi-Ion battery charging and balancing boardsAC/DC Mains powers supply adapterPower Supplies AC/DCConnection Cables, ExtendersBatteries for power toolsPlug adapter EU/UK/USCharger for Electric Bikes

Soldering toolsBattery Welding Machines and accessoriesMeasuring equipmentChemicalsTweezersElectric toolsScrewdrivers and wrenchesHot Glue GunPlier and cutting nipperInsulation removal and crimping toolKnives and scissorsElectric engraver toolsMagnifying glassesInsulating materialsFlashlightPlastic enclosureStorage boxes and OrganizersUltrasonic cleanersLabel printersAIRCELL Air Cushion

CNC machines and accessoriesAluminum Extrusion ProfilesLinear ActuatorBrackets and Other Accessories for Aluminium ProfilesLinear guides and garriagesRollers on supportsTrapezoidal Screws and NutsLinear Steel RodsLinear bearingsBearingsTiming BeltsTiming PulleyLinear Rod SupportSpindle motors, converters and mount bracketsScrews and NutsCable ChainsDrills and Cutters

AEON Laser Engraving Cutting MachineFiber Metal Marking LaserCO2 Galvo engraving-marking machineUV Marking machineFLUX Laser Engraving Cutting MachinexTool LASER AND BLADE CUTTING MACHINEDiode laser engraving laserLaser machine spare parts and accessoriesEngraving MaterialsLightBurn Software

3D Printers3D scanner3D Pens3D Printing filamentsSLA 3D Printing resin3D Printer maintenance and cleaning3D Printer parts

Educational kits for beginnersEducational kits for advancedSNAP CIRCUITS kitsAbilix Krypton roboticsRobobloq roboticsLEGO Education

USB cablesVideo cables and connectorsUSB HUBComputer network cablesNetwork equipmentData storages and their accesoriesAudio cables and connectorsSpeakers activeKeyboard and MouseMicrophonesGamingLaptop AcessoriesComputer Power SuppliesCable OrganizersMonitorsWebcamsProjectorsUPS Uninterruptible power supplyOther Computer Accessories

Power BankHeadphonesMobile phone chargersPhone casesSelfie stickSmart WatchesPhone batteriesPortable speakers

Jump StartersCar Dash CamerasPhone holdersCarPlay and Android AutoMotorcycle IntercomsUSB car chargersCar FM modulatorEV Car accessoriesCar StorageCar diagnostic equipmentCar Cleaning ToolsMini CompressorsParking HeatersCar fuses and holdersLight sources

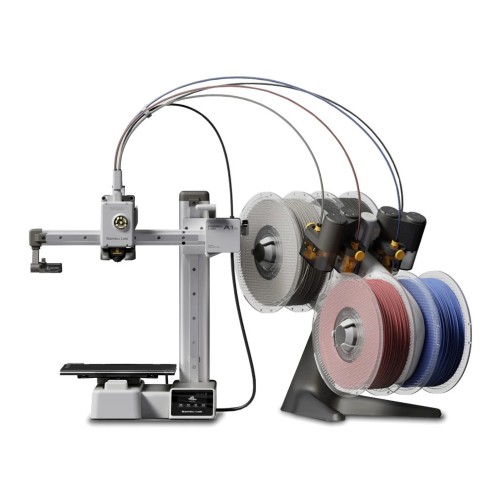

3D printer - Bambu Lab A1 mini Combo

Brand: Bambu Lab

Product Code: AN-24565

Availability: Vilnius Store In Stock

Kaunas Store Out of Stock

Central Warehouse Out of Stock

Product Code: AN-24565

Availability: Vilnius Store In Stock

Kaunas Store Out of Stock

Central Warehouse Out of Stock

Ex Tax: 369.50€

The Bambu Lab A1 Mini 3D Printer is a FDM 3D printing game changer that redefines flow control. It uses a high-resolution, high-frequency eddy current sensor to accurately measure nozzle pressure. The A1 mini is pre-assembled, pre-tuned and fine-tuned. It only takes about 20 minutes to set up your first print. This combo kit includes the all-new AMS lite, which is sleek and reliable, making multi-color 3D printing accessible to everyone.

Features:

- Plug-N-Play convenience

- Active flow compensation

- Full automatic calibration

- Active engine noise suppression

- High speed accuracy

- Active flow compensation

- 180x180x180mm Maximum construction volume

- Includes AMS Lite

Plug-N-Play

The A1 mini is pre-assembled, pre-tuned and fine-tuned. It only takes about 20 minutes to set up your first print.

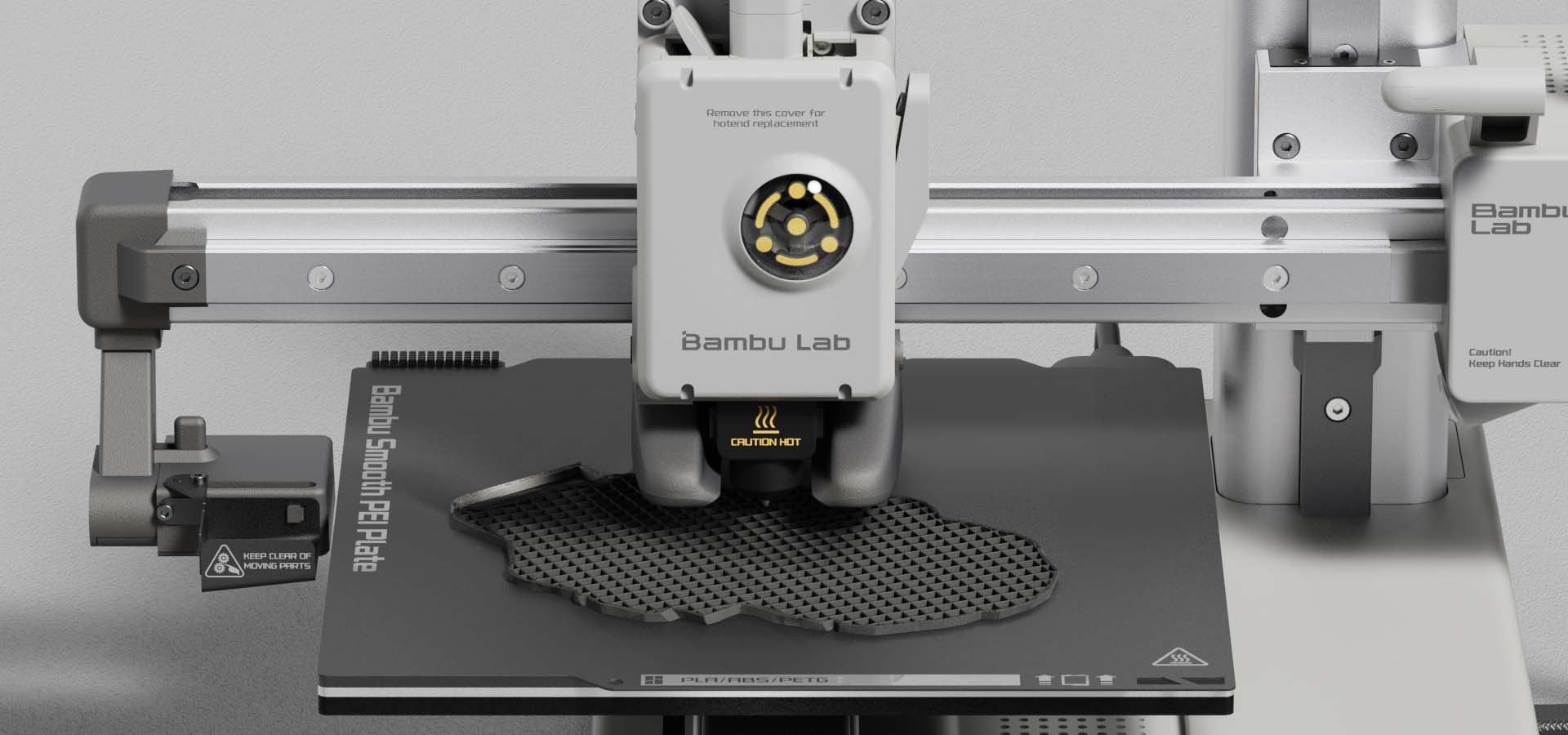

Fully automatic calibration

The A1 mini performs various calibrations on its own. It carefully auto-calibrates Z-shift, bed level, vibration resonance and nozzle pressure for EVERY print job.

Automatic Z shift

The A1 mini-probe in bed with a tip measures the absolute z-displacement. No need to stick paper as a reference.

Automatic vibration calibration

The A1 mini has sensors in the tool head and heating bed. One of the first bed-mounted printers to perform automatic resonance calibration in both X and Y axes.

Automatic flow dynamics

The first of its kind, the A1 mini runs a nozzle pressure-based flow dynamics calibration algorithm. No need to draw any pattern or manually select and match, the A1 mini grip pressure advanced calibration is done automatically.

Automatic belt tensioning

The A1 mini can automatically check belt tension by calibrating the vibration frequency. If the belt is loose, the HMS system will tell you to use the automatic belt tensioner to keep the belt properly tensioned.

Print smoothly in every corner, every time

The A1 mini revolutionizes flow control in the field of 3D printing. A high-resolution high-frequency eddy current sensor is used to measure the pressure in the nozzle. Our algorithm actively compensates for flow based on readings for accurate compression.

High speed accuracy

Full metal rails, rigid frame, nozzle pressure sensor, accelerometers, a powerful MCU and most importantly an advanced motion control system that uses these features to print a 14-minute bench in high quality while complying with all speed setting rules. box without using specialized threads.

Quick change nozzles

All-new quick-change hotend design that pops in and out with just one click.

Print quietly

Active motor noise reduction and silent mode can reduce noise levels to less than 48dB, making the A1 mini one of the quietest 3D printers on the market, so you can take a nap while the printer is hard at work.

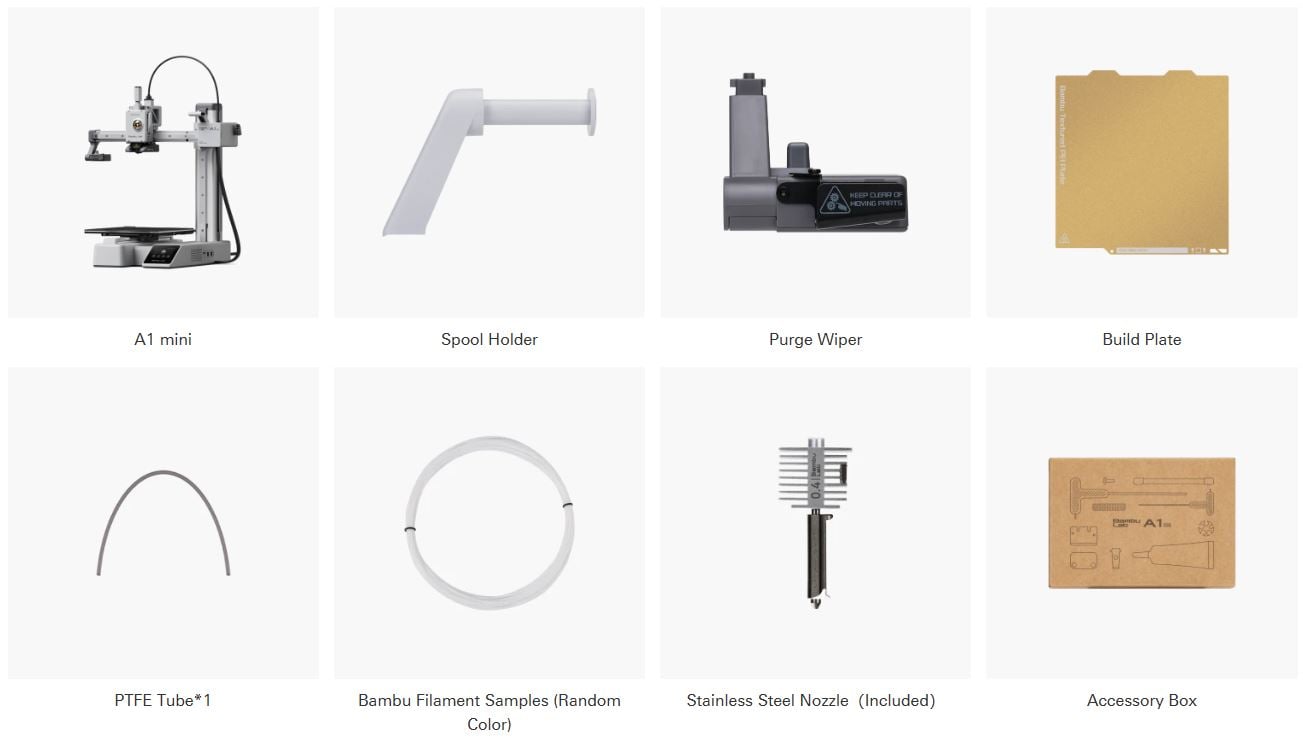

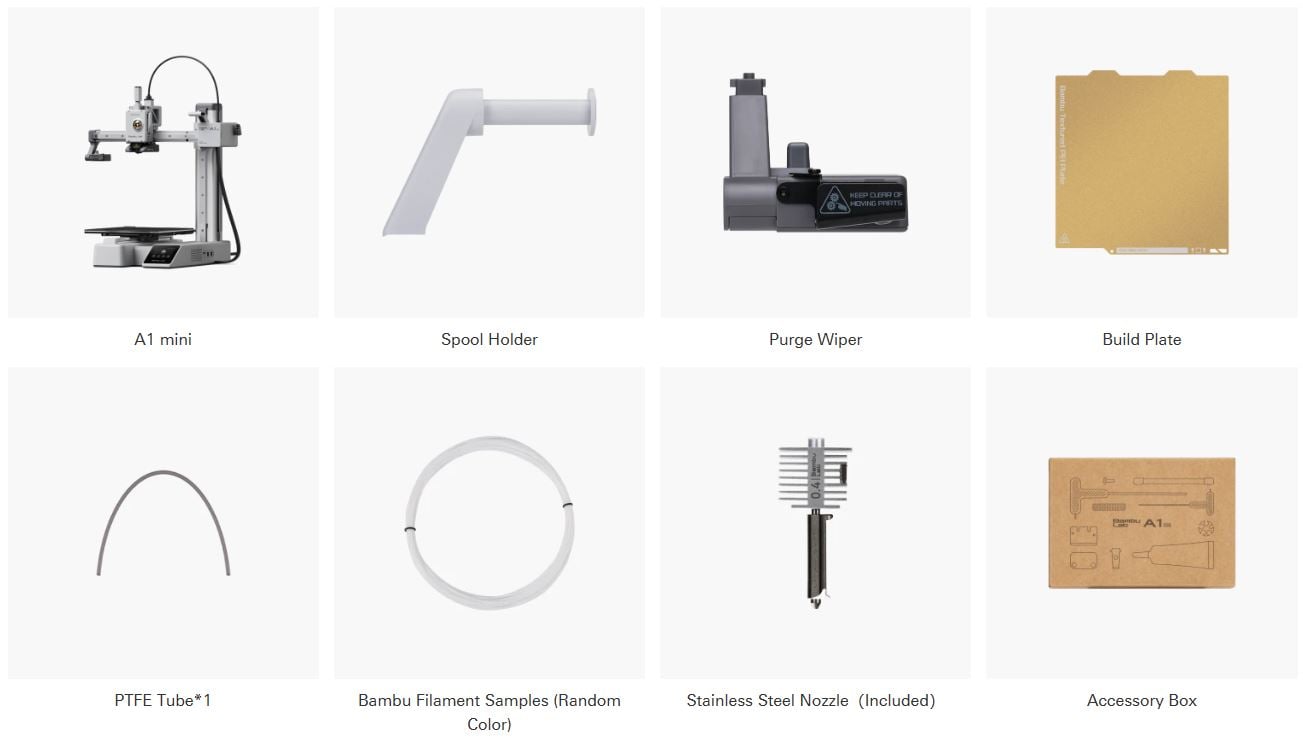

In the set:

Construction and technical details

- Used thread diameter: 1.75mm

- Maximum nozzle temperature: 300 ºC

- Open thread system: Yes

- Recommended maximum print speed: 500 mm/s (

- Working area: 180x180x180mm

- Maximum temperature of the construction plate: 80 ºC

- Construction board surface: PEI

- Creation Chamber in Process: Opened

- Heated building chamber: No

- Thread chamber closed: No

- Extruder number: 1

Installation location / Requirements

- Total weight Total dimensions: 347x315x365mm

- Total weight: 5.5kg

- Maximum power consumption: 150W

- Voltage: AC: 100V 240V (50-60 Hz)

Equipment

- Emergency shutdown: No

- Hepa filter: No

- Door sensor: No

- Door lock during printing: No

- Filament leakage sensor: Yes

- Filament clogging sensor: Yes

- Safe Power Loss: Yes

- Touch screen: Yes

- Camera: No

Connection

- SD card: No

- USB port: No

- Ethernet port: No

- WLAN: Yes

Accuracy

- Shipping

- Shipping box: 385x430x430mm

- Shipping weight: 8.2kg